Argon in insulating glass units

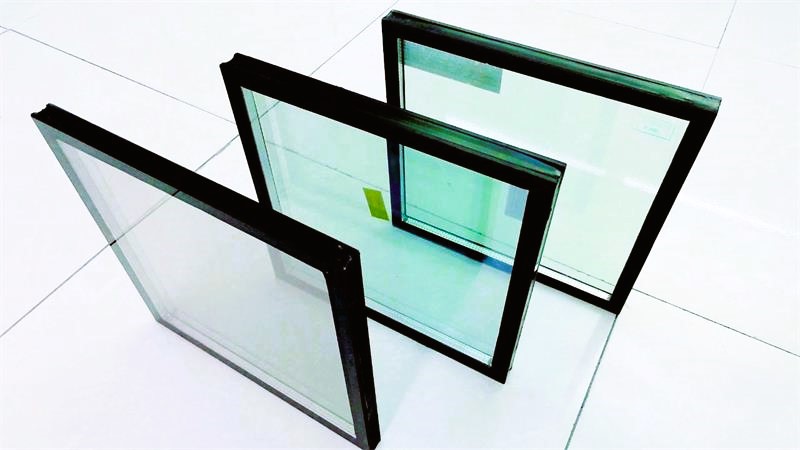

Insulating glass units, also known as double or triple glazing, have revolutionized the window industry by offering improved thermal performance and enhanced comfort for buildings. One important component of these units is the insulating gas used to fill the space between the glass panes. Argon, a colorless and odorless gas, is commonly utilized in insulating glass units to enhance their energy efficiency and overall performance.

Argon is an inert gas that is denser than air, which makes it an excellent insulator. When injected into the space between the glass panes, it acts as a thermal barrier, reducing heat transfer and improving the insulation properties of the window. This helps to maintain a more stable indoor temperature, reducing the need for excessive heating or cooling and ultimately lowering energy consumption. Innovative features of modern designs of plastic windows, more details in our article.

The use of argon gas in insulating glass units provides several key benefits:

- Enhanced Thermal Efficiency: Argon gas has a lower thermal conductivity compared to air. By replacing the air between the glass panes with argon, the insulating properties of the window are significantly improved. This results in reduced heat loss during the colder months and decreased heat gain during the hotter months, creating a more comfortable indoor environment and lowering energy costs.

- Improved Sound Insulation: Argon gas also aids in reducing noise transmission through the window. Its higher density compared to air helps to dampen sound vibrations, resulting in better sound insulation. This is particularly beneficial for buildings located in noisy environments or near busy streets, airports, or railways, as it helps to create a quieter and more peaceful living or working space.

- Minimized Condensation: Condensation on the interior surface of windows can be a common issue, particularly in colder climates. By filling the space between the glass panes with argon gas, the temperature difference between the interior and exterior surfaces of the window is reduced. This helps to minimize the likelihood of condensation forming on the glass, improving visibility and preventing potential damage to the window frame or surrounding surfaces.

- Long-Term Stability: Argon is a stable and non-reactive gas, meaning it does not corrode or degrade the materials used in the window construction. This ensures the long-term performance and durability of the insulating glass unit, contributing to the longevity of the window and reducing the need for frequent replacements.

It is worth noting that argon gas is just one option among several gases used in insulating glass units. Other gases, such as krypton and xenon, offer even lower thermal conductivity but come at a higher cost. Argon strikes a balance between performance and affordability, making it a popular choice in the industry.

In conclusion, the use of argon gas in insulating glass units provides numerous benefits, including enhanced thermal efficiency, improved sound insulation, minimized condensation, and long-term stability. By incorporating argon-filled insulating glass units in windows, buildings can achieve higher energy efficiency, increased comfort, and reduced environmental impact.